Laser diode pigtailing and packaging using Nd:YAG laser welding technique

DOI:

https://doi.org/10.31258/jkfi.5.11.203-208Keywords:

Single mode fiber, coupling efficiency, laser welding systemAbstract

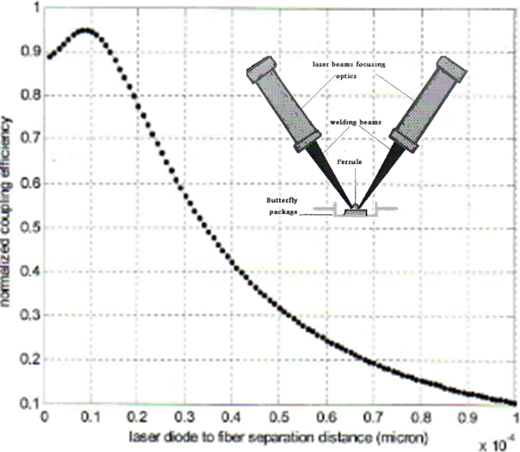

In this paper we present some investigations and analysis of various parameters that contribute for increasing the coupling efficiency of laser diode to single mode fiber coupling using lens coupling and butt coupling schemes. The fiber attachment process and the fixing of various coupling components have been performed in what is so called active alignment process, where the system continues measuring the coupled power during the process of coupling and welding of (lens holder, fiber ferrule, and welding clips), Nd:YAG laser welding system (LW4000S from Newport) has been used for the alignment and welding of the coupling components. Results of optimizing laser beam parameters to get good welds with small heat affected zone (HAZ) such as (variation of weld dimensions with changing of laser beam parameters are also presented. We also studied the weldability of different materials to determine the suitability of using those materials as the base material and welding tools for different types of photonic devices packaging.